Casting, Machining & Manufacturing Services

Since 1933, Farrar Corporation has provided high-quality ductile iron castings, heat treating/annealing, state-of-the-art CNC machining, custom design and engineering, full assembly capabilities, and efficient delivery services. Our commitment to quality and innovation continues to be of utmost importance, allowing us to offer comprehensive solutions from concept to completion.

As an ISO 9001-registered company equipped with a modern CNC machining facility, Farrar Corporation possesses the expertise and resources to meet your most challenging manufacturing requirements. Trust us to deliver precision, reliability, and excellence for all your industrial needs.

Precision Pattern-Making & Casting

Our Norwich facility houses a comprehensive pattern shop that is integrated with our foundry operations. We understand that the ultimate quality of a casting is inherently linked to the precision of its pattern and respective core box. This is why we take immense pride in crafting our tooling in-house, utilizing our expertise and advanced equipment to ensure unparalleled accuracy.

By maintaining control over the entire process, from pattern creation to final casting, we guarantee the highest quality products for our clients. Our skilled craftsmen and state-of-the-art technology work in harmony to produce patterns that meet exacting standards, resulting in castings that consistently exceed expectations.

This integrated approach allows us to maintain strict quality control, optimize efficiency, and respond quickly to custom requirements. At Farrar Corporation, our commitment to excellence begins with the very foundation of the casting process – the tooling – and extends through every stage of production.

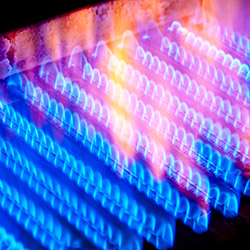

Quality Heat Treating Services

For clients requiring annealed castings, our state-of-the-art heat-treating capabilities ensure your products receive optimal treatment. Our facility features a custom-designed system that integrates cutting-edge technology with streamlined processes.

At the heart of our heat-treating operations are three fully programmable furnaces, interconnected by an automated material handling system. This advanced setup extends to include a cooling chamber and a shot blast machine, creating a seamless production flow.

The automation of our system eliminates the need for manual interaction for loading and transfers to cooling and shot blasting, significantly enhancing production speed and efficiency. This streamlined approach not only accelerates the manufacturing process but also minimizes the potential for human error.

By maintaining complete control over the entire heat-treating process, we ensure consistent quality while reducing both time and costs. This integrated system allows us to deliver superior annealed castings that meet the most exacting standards, all while optimizing resource utilization.

Advanced CNC Machining

Our CNC machining operations are designed to handle the specific sizes and weights of castings produced in-house, ensuring optimal efficiency and precision. This tailored approach allows us to seamlessly integrate casting and machining processes, minimizing handling and maximizing quality control.

However, our capabilities extend far beyond our captive casting production. We’re equipped to machine castings that surpass our in-house casting size limits, as well as components made from a diverse range of materials. This flexibility allows us to meet a wide spectrum of client needs, from small, intricate parts to large, complex components.

By maintaining our own CNC machining facility, we create a streamlined manufacturing ecosystem. This integration offers numerous advantages: enhanced quality control across the entire production process, reduced lead times through efficient workflow management, cost-effectiveness by eliminating third-party machining expenses, improved communication and problem-solving between casting and machining teams, and greater flexibility in accommodating custom orders and design modifications.

At Farrar Corporation, our in-house CNC machining capabilities not only complement our casting expertise but also reinforce our commitment to delivering comprehensive, high-quality manufacturing solutions. Whether you need castings machined to precise specifications or require machining services for externally sourced components, our advanced CNC operations are ready to meet your needs with uncompromising quality and efficiency.

ISO-Certified Assembly Services

Farrar Corporation offers expert, ISO-certified assembly services, extending our commitment to quality beyond casting and machining. We transform individual components into fully assembled, ready-to-use products, streamlining your supply chain and accelerating time-to-market.

Our comprehensive approach covers every aspect of quality manufacturing through final assembly, maintaining stringent control throughout. We’ve demonstrated our capability by delivering over 300,000 expertly assembled units to a single client, each ready for immediate integration into their production line.

At Farrar, we’re not just manufacturers; we’re your partner in creating complete, market-ready solutions. Our assembly services offer the convenience of a single-source supplier, ISO-certified quality assurance, and the flexibility to meet diverse production needs. Let us handle the complexities of assembly while you focus on growing your business.